By Henrylito D. Tacio

(Photos courtesy of PNRI/DOST)

Pollution comes in different forms: air, water, soil, and even noise. In the Philippines, one of the most pressing problems is water pollution, according to the Water Environment Partnership in Asia (WEPA).

The effects of water pollution cost the Philippines approximately P67 billion annually. These include P3 billion for health, P17 billion for fisheries production, and P47 billion for tourism.

“Large amounts of water pollution have caused an overall depreciation of public health in the Philippines,” wrote Gabriella Andrews in her study published in the Pepperdine Policy Review. “Poor health reduces labor efficiency while simultaneously decreasing life expectancy, thus creating a health-induced poverty trap.”

Past administrations, including the current one, have passed several water-related laws. Still, their enforcement seems weak and beset with problems. “The government continues to try to clean up the problem, implementing fines to polluters as well as environmental taxes, but many problems have not been addressed,” Borgen magazine observed.

There are several ways of skinning a cat, so goes a popular saying. In like manner, there are various methods of solving the water pollution the country is now facing. One of those that scientists have identified as another solution to the worsening water pollution is abaca.

Using abaca, the country is literally hitting two birds with one shot: helping solve the water pollution problem and encouraging farmers to plant more abaca, which is endemic in the country.

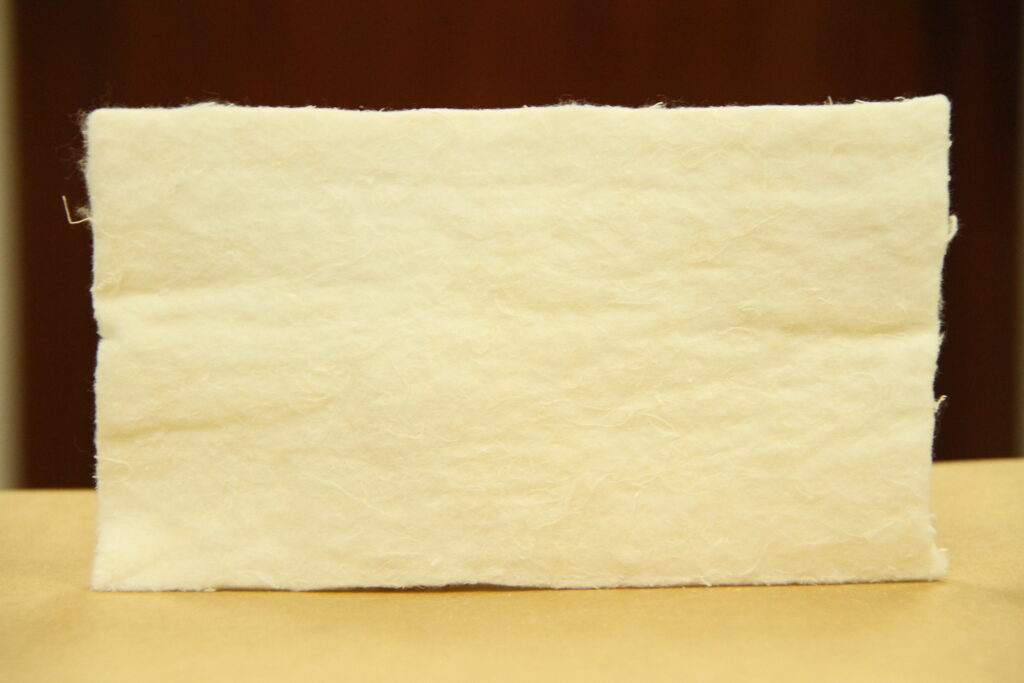

In a study conducted by the Philippine Nuclear Research Institute (PNRI), a line agency of the Department of Science and Technology (DOST), researchers used radiation techniques to modify abaca-based fabric into a material that can filter heavy metals from wastewater.

Among the heavy metals identified were lead, cadmium, nickel, chromium, mercury, and arsenic—all these metals, which are highly soluble in water, harm human health and the environment.

“The danger that these heavy metals pose to living things make it necessary to treat wastewater before discharging it to the environment,” the PNRI said in a press statement.

“To trap toxic metals, the research team used radiation to graft an abaca-based nonwoven fabric with super tiny filters that can separate or remove the dissolved toxic metals from the wastewater,” wrote Framelia G. Viernes-Anonas, PNRI’s supervising science research specialist.

The institute’s Electron Beam Irradiation Facility provided the radiation used in the study.

“Radiation can modify and graft various materials with advanced properties,” explained Dr. Jordan Madrid, head of the PNRI’s Chemistry Research Section.

The research team found that radiation-modified nonwoven fabric is at par, if not better, than commercial resins which are traditionally used in filtering heavy metals.

More importantly, the abaca fiber is cheaper and reusable.

Aside from its potential use as an effective filter for pollutants, the researchers are also exploring other radiation-treated abaca fabric applications, such as in recovering precious metals and as a catalyst for producing biodiesel.

The technology’s potential to clean up the environment was recognized when it bagged the utility model award in the Regional Invention Contest, and the Exhibits-National Capital Region held last year. It was also named the Outstanding Utility Model in the National Invention Contest and Exhibited early this year.

The technology is a collaborative work among three DOST agencies. Aside from PNRI, which provided the applied radiation technique to the nonwoven abaca fabric, the two other agencies involved were the Philippine Council for Agriculture, Aquatic and Natural Resources Research and Development (PCAARRD), which funded the project, and the Philippine Textile Research Institute (PTRI), which provided the abaca/polyester nonwoven fabric.

“When adopted by local governments and private institutions, this technology can likewise bolster the country’s status as the world’s leading abaca producer, contributing 84% of the world’s production and earning P4.7 billion for the country annually,” Anonas wrote.

Abaca fiber mask

AbacaAbaca used to be called “Manila hemp,” but it is not actually hemp. Unlike the Russian hemp or American hemp, both derived from Cannabis sativa, abaca is a banana family member.

“Abaca has been grown in the Philippines for centuries, long before the Spanish occupation,” reports the Philippine Fiber Industry Development Authority (PhilFida). “When (Ferdinand) Magellan and his companions arrived in Cebu in 1521, they noticed that the natives were wearing clothes made from the fiber of abaca plant, noting further that the weaving of the fiber was already widespread in the island.”

However, it was not until 1685 that abaca was known in the Western world. Then, in 1820, John White, an American Navy lieutenant, brought abaca fiber samples to the US. A cargo of abaca was sent to Salem, Massachusetts, under the label “Manila.” The Americans later became the largest abaca importers as Manila’s port was opened for international trade in 1834.

“The Japanese also took a keen interest in abaca for naval use,” wrote Ernesto Lawagan in an article that appeared in the defunct Mod. “They improved the method of production introduced by the Americans and put the abaca industry in the Philippines to a higher level of efficiency.”

In the 1920s, the Philippines monopolized the world production of abaca fibers, which are obtained from the plant leaves. “In 1921, the U.S. Department of Agriculture decided to cultivate abaca in Central America, particularly in Panama, Costa Rica, Guatemala, and Honduras, using the most outstanding Philippine abaca varieties. Much of these resulted in failure,” Lawagan wrote.

After World War II, Furukawa Yoshizo, one of Davao’s prewar abaca plantation owners, started field-testing and successfully cultivating abaca in Ecuador. “Today, Ecuador is the only other country commercially producing abaca in the world,” Lawagan noted. “Costa Rica, on the other hand, is now developing modern harvest facilities as studies indicated that its land could accommodate high yields of the crop.”

In later years, on the onrush of modern technology, abaca was no longer given importance and was relegated to the background. “The advent of oil-based synthetic fibers in the mid-1950s, which rapidly replaced the traditional usage of natural fibers, displaced abaca as prime cordage material and precipitated its almost total collapse,” Lawagan wrote. The Philippine abaca industry suffered a slump as prices hit rock-bottom that several farmers eventually phased out their plantations.”

Stages a comeback

But thanks to the global shortage of many natural resources and the pollution being wrought by synthetic products on the environment, abaca stages a comeback. “Significant breakthroughs in technology and processes took place in the ’60s that brought about development of new uses for abaca, particularly in the use of pulp for the production of specialty paper products,” PhilFida reported.

Agriculturists say the country’s agro-climatic conditions are perfect for growing abaca, which many people still mistake for banana plants. In the Philippines, abaca has been found growing in virtually all types of soils and climate. But it is found most productive in areas where the soil is volcanic in origin, rich in organic matter, loose, friable, and well-drained, clay loam type.

Abaca is prized for its great mechanical strength, resistance to saltwater damage, and long fiber length – up to 30 meters. The best grades of abaca are fine, lustrous, light beige in color, and very strong.